Choose the right industrial razor blade [PDF] | Sollex

Sollex tips on how to choose the right industrial knife and what should affect the choice. When choosing a knife, you need to consider a number of factors, which in turn affect the material from which the knife is made, its coating, thickness and shape. At the end of the article you can find a complete Sollex catalog of knives and razor blades for industrial applications.

Different coatings prolong blade lifetime and cutting quality. As an extra benefit coatings can improve surface finish and reduce friction which reduces heat and wear.

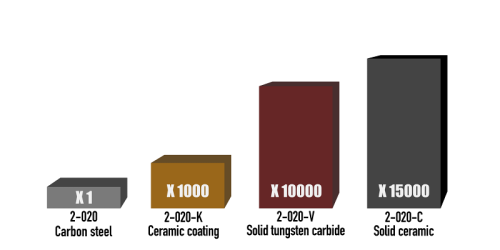

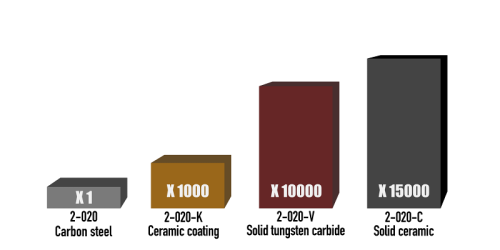

Optimized materials increase blade lifetime. Depending on your slitting process we are able to engineer blades that will outlast and outperform wear resistant materials. Sollex makes blades in the following materials: Carbon steel, Stainless Steel (SS), Tooling steel, HSS-M2 steel, D2 steel, Tungsten Solid Carbide, Solid ceramic.

Most blades and materials are engineered to be positioned at a 45 degree angle to the material. Lower angles give slicing motion and spread wear out over more of the cutting surface.

A clean surface finish or cutting edge will lower the friction which reduces heat and wear. This results in cleaner edge cuts.

Multi-facet grinding and burr free edges give the best cutting results, cleaner edge cuts and reduced web breaks.

Industrial knives are used in a variety of industrial applications:

- film and foil manufacturing

- packaging manufacturing

- plastic extrusion

- plastic pelletizing

- fiber, textile and non woven cutting

- food processing

- precision cutting

- digital plotter cutting

- advertising sign production

Such knives are often used for processing the following types of material:

- Adhesive film

- Coated film

- Rubber

- Foam

- Cardboard

- Paper

- Textiles

- Non woven

- Polycarbonates

- PVC

- PP

- PC

- LDPE

- LLPDE

- EBA

- HDPE

Coating performs

Different coatings prolong blade lifetime and cutting quality. As an extra benefit coatings can improve surface finish and reduce friction which reduces heat and wear.

Thickness performs

Thinner blades perform better. Therefore you should try to use the thinnest blade possible. A thinner blade demands less force and gives less shear in the material you are slitting. A thinner blade is helpful to avoid web breaks and gives a better cut.

Material performs

Optimized materials increase blade lifetime. Depending on your slitting process we are able to engineer blades that will outlast and outperform wear resistant materials. Sollex makes blades in the following materials: Carbon steel, Stainless Steel (SS), Tooling steel, HSS-M2 steel, D2 steel, Tungsten Solid Carbide, Solid ceramic.

Angle performs

Most blades and materials are engineered to be positioned at a 45 degree angle to the material. Lower angles give slicing motion and spread wear out over more of the cutting surface.

Surface finish performs

A clean surface finish or cutting edge will lower the friction which reduces heat and wear. This results in cleaner edge cuts.

Edge quality performs

Multi-facet grinding and burr free edges give the best cutting results, cleaner edge cuts and reduced web breaks.

You can save money by using double sided blades where all four corners of the blade are used. Sollex reduces your costs and inventory.

More information: https://www.sollex.se

Sollex is a supplier of knives and blades in Europe. We have products with cutting edge technology and performance that improve the cutting processes and solve problems.

Contact person: Johan Falk, CEO

Contact person: Johan Falk, CEO

Mob: +46 35-15 75 00

Mail: info@sollex.se

Web: www.sollex.se

SOLLEX – Cutting edge performance

Download our catalog for manufacturers of plastic film and packaging, where you can find a more detailed table on what knife coating to choose for cutting a certain material

Comments

Post a Comment